Chimney Design Effects

There are several Class A chimney designs. First, there’s “air cooled” chimney, which can be double or triple walled. Then there is “insulated” chimney, which was developed for colder climates as it drafts better. It is not recommended that air cooled chimney be used in an exterior installation in northern climates.

When it comes to insulated Class A chimney designs, there are some variations to consider. Some designs are actually a hybrid between air cooled and insulated chimney. Below is a triple wall chimney with the outer wall air cooled and the inner wall insulated. This is better than an air cooled chimney, but not recommended for northern climates.

Insulated Class A chimney, or “solid pack chimney”, is recommended for northern climates. There are some variations in insulated chimney pipe: Some brands are encapsulated, meaning the insulation is inside the two walls of the chimney and is sealed on both ends. This design is much better than triple-wall chimney as it has thicker insulation and no airspace. The drawback of this design is that there is no place for any condensation that may form inside the chimney section, to escape.

Exterior chimneys installed in northern climates are especially susceptible to developing condensation because they are allowed to cool down and then re-heated. Better insulation equals better R-value. Chimneys that have a low R-value generate more condensation than chimneys with higher R-values. The thicker the insulation in solid pack chimney, the less likely it is to be affected by the weather. It will heat up faster when cold, produce more draft, and stay cleaner and hotter for longer periods of time. You will find the best chimney brands that offer class chimney systems in Canada as well as the U.S. are usually not fully encapsulated on each end. The end caps on each section of chimney is designed so that moisture can escape, preventing it from building up inside the insulation and reducing the chimney’s R-value with age.

Chimney fires are fairly common with burning wood, so a chimney should be designed and installed accordingly. The chimney should survive the chimney fire and not burn down the structure in the process. Therefore, the National Fire Prevention Association developed NFPA 211 as a guide to help the industry standardize national building codes concerning chimneys. Manufactured Class A chimneys should survive a chimney fire and are tested to insure that they do not transmit radiant heat to combustibles if installed properly.

The danger begins when a chimney fire occurs and the interior temperatures of the space between the inner wall and the outer wall of the encapsulated chimney increase to the level where the moisture begins to boil creating steam. Steam expands rapidly, and if there is nowhere for the steam to vent, pressure will build until something ruptures. A ruptured chimney is a compromised chimney.

Choosing a chimney design with thicker walls, better insulation properties, and good ventilation is preferable in colder climates, especially in an exterior installation. It is also advisable to enclose an exterior Class A chimney inside a chimney chase to help insulate it from the wind and cold. In cold climates, insulating the chase will also help keep the chimney warmer, so it will perform better.

Below is an example of a proper installation of an exterior Class A chimney system in a cold climate, installed by Obadiah’s Woodstoves.

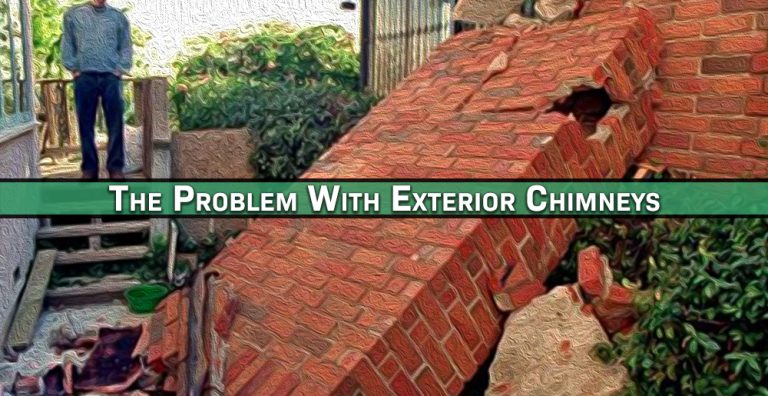

Overhangs and soffits present other issues when installing an exterior chimney on an existing structure. It is always advisable to penetrate the overhang verses going around them utilizing offsets in your Class A chimney system.

Below are some common examples of utilizing offsets to bypass overhangs as well as windows. Please keep in mind that all offsets must be properly supported so that stress is not placed on any elbows in a Class A chimney offset installation. The weight of the chimney pressing down on the elbows could cause the elbow, or the offset, to fail. You must install a support bracket at this point to the fascia of the overhang which can carry the weight of the chimney above. Notice the second picture does not have a support bracket at the fascia level to support the weight of the chimney: The stabilizers provide lateral protection, but not vertical. The picture on the right has no lateral or vertical support, and is at risk of failure due to its improper installations. On complicated installations, we recommend that you call Obadiah’s Woodstoves and ask for a chimney specialist to help you.

Class A chimney that meets the more rigid Canadian ULCS 629 listing tend to be thicker with a higher R-value, to reduce condensation issues in extremely cold climates. The exception is Excel Chimney which is only 1″ thick as well as one of the lightest weight Class A chimney systems on the market. This makes a difference if installing chimneys is your profession, which is why this brand is preferred (it is sold by professionals and generally not found at a discount online). Olympia Chimney is a U.S. company that has taken over a large share of the North American market, and they offer high quality Class A chimney systems that meet both the U.S. UL Standards and the more stringent Canadian ULC Standards called “Ventis”. In 2019, Olympia Chimney purchased a competitor, Copperfield Chimney, giving them a massive base of chimney professionals as customers.

Condensation occurs between two surfaces of differing temperatures and is called the “dew point”. An every day example of this is a beverage on ice: The outside of the glass will condensate in a warm environment, and with higher humidity the process intensifies. In the case of a chimney, the physics are the same, but the chimney is hot instead of cold and the environment is cold instead of hot.

This issue of condensation building up inside of an encapsulated chimney increases the more the moisture levels build, because the moisture further reduces the R-value of the insulation.

The Canadian ULC standard is generally considered the toughest residential chimney standard in the world. It would only stand to reason that purchasing Class A chimney that meets the ULC S629 listing would be the best choice in terms of safety because of the way the test is conducted. The Canadian ULCS standard requires the chimney to withstand three 30-minute chimney fires, three times longer than tests in the U.S. You can purchase Class A chimney in the U.S. that meets the Canadian 629S standard if you know what to look for it, but it is not generally imported into the U.S as distributors here do not stock Canadian chimneys for the U.S. market. Excel Chimney, Ventis Chimney, Dura Vent, Security Chimney, and Selkirk are a few manufactures who build chimneys in Canada. Some offer Class A chimneys that carry both a ULC and a UL Listing, for example Excel, Ventis, Dura Tech Premium, and Security ASHT+.

The US Class A Chimney UL listing comes in variations as well, since not all Class A chimney standards require the same levels of testing. If you are shopping for Class A chimney, it would be wise to understand what UL Standard the chimney you’re looking at investing in meets. You should also know that manufacturers can do their own testing if they build their own lab and follow certain guild lines. Nobody re-tests their results to verify their accuracy, and this is worth knowing as a consumer because there are always companies that will cut corners to increase profits. You should always buy your chimney components from reputable companies that specialize in heating or chimneys. Big box stores do not offer the same grade Class A chimney as a professional who will be there for you if there is an issue. Mass merchants hire people were flipping burgers down the road last week, so you have to ask yourself: How much do you think they know about what they sell?

ULC/ UL Listings for Class A Chimney – These listing apply to factory built chimney systems and fireplaces:

According to UL-103HT, UL-103, ULC-S604, and ULCC959: For solid fuel application by Underwriters Laboratories in the United States and Canada, the chimney shall be listed for temperatures not exceeding 1000°F (538°C) under continuous firing and 1400°F (740°C) in brief forced firing.

According to UL/ULC HT listing for solid fuel application by Underwriters Laboratories in the United States and Canada, the chimney shall be listed for temperatures not exceeding 1000°F (538°C) under continuous firing and 1400°F (740°C) in brief forced firing. Tested to 2100°F (1150°C) – 10 minutes – 1 time.

UL 103: 1000 degrees F continuous, 1400 degrees F 1 hour, 1700 degrees F 10 min. This applies primarily to prefabricated chimney systems.

UL 103 Scope-USA

1.1 These requirements cover factory-built chimneys intended for venting gas, liquid, and solid-fuel fired residential-type appliances and building heating appliances in which the maximum continuous flue-gas outlet temperatures do not exceed 1000°F (538°C). Factory-built chimneys are intended for installation in accordance with the Standard for Chimneys, Fireplaces, Vents, and Solid-Fuel Burning Appliances, NFPA 211, and in accordance with codes such as the International Mechanical Code, the International Residential Code, and the Uniform Mechanical Code. They are intended for installation inside or outside of buildings or both, in a manner that provides a vertical (30 degree maximum offset) conduit or passageway to transport flue gases to the outside.

1.2 The chimneys covered by these requirements comply with either a limited duration 1700°F (927°C) flue-gas temperature test or a limited duration 2100°F (1149°C) flue-gas temperature test, at the manufacturer’s option.

1.3 These requirements cover dual purpose residential type and building heating appliance type chimneys, and single purpose building heating appliance type chimneys. Dual purpose residential type and building heating appliance type chimneys are tested enclosed and intended to be installed unenclosed or enclosed with combustible construction. Single purpose building heating appliance type chimneys are tested unenclosed and intended to be installed unenclosed or enclosed in a noncombustible chase.

UL103HT: 1000 degrees F continuous, 2100 degrees F three intervals 10 minutes.

Note: UL103HT Chimney follows the same 103 scope, rather than one 1700 degree F 10 minute test, it is increased to three 10 minute tests at 2100 degrees F. This is a substantial difference in a chimneys ability to withstand a chimney fire.

UL127: A 1700 degree F test, or at MFG option; a 2100 degree F Test.

Note: This is very vague language as it does not spell out much in terms of duration or survivability. This type of chimney cannot be re-used for other purposes as it is tested to such a low standard.

Pertains to Factory Built Fireplaces, The Combustion Chamber, Field Assembled Chimney and all necessary components to assemble it in the field. Usually Air Cooled Chimney. Is not approved for use with any solid fuel appliance other than those it was tested with.

1 Scope-USA

1.1 These requirements cover factory-built fireplaces, including the fire chamber, chimney, roof assembly, and other related parts that are entirely factory-made and that are intended for unit assembly in the field.

1.2 These requirements cover factory-built fireplaces having a fire chamber intended to be operated either open to a room or, when equipped with doors, operated with the doors either open or closed.

1.3 These requirements cover factory-built fireplaces intended for use with either solid wood or coal fuels.

1.4 The factory-built fireplaces covered by these requirements are intended for installation in accordance with the National Fire Protection Association Standard for Chimneys, Fireplaces, Vents and Solid-Fuel Burning Appliances, NFPA 211, the International Mechanical Code, and the Uniform Mechanical Code.

1.5 As covered by these requirements, an air duct system portion of a circulating warm air type fireplace is intended for installation in accordance with the National Fire Protection Association Standard for Warm Air Heating and Air Conditioning Systems, NFPA 90B.

1.6 These requirements also cover fixed blowers, and other electrical accessories for factory-built fireplaces, rated at 600 volts or less, and intended to be employed in specified locations in accordance with the National Electrical Code, NFPA 70.

1.7 The chimneys for factory-built fireplaces covered by these requirements comply with either a 1700°F (927°C) flue-gas temperature test or a 2100°F (1149°C) flue-gas temperature test, at the manufacturer’s option.

1.8 A product that contains features, characteristics, components, materials, or systems new or different from those covered by the requirements in this Standard, and that involves a risk of fire, electric shock, or injury to persons shall be evaluated using the appropriate additional component and end-product requirements to determine that the level of safety as originally anticipated by the intent of this Standard is maintained. A product whose features, characteristics, components, materials, or systems conflict with specific requirements or provisions of this Standard shall not be judged to comply with this Standard. Where appropriate, revision of requirements shall be proposed and adopted in conformance with the methods employed for development, revision, and implementation of this Standard.

ULC S604: Standard for factory-built type A chimneys- primarily same standard as UL 103HT. 1000 degrees F continuous, 1400 degrees F 1 hour, 2100 degrees F. 10 min x 3

SCOPE-CAN-Partial

These requirements apply to Factory-Built Type A Chimneys, which do not require field fabrication. They are for use with gas and liquid fuel-fired residential appliances and building heating equipment, where the appliance or equipment flue-gas temperatures do not exceed 540 °C. They are intended for use in accordance with the National Building Code of Canada, CSA-B139.2, Installation Code for Oil Burning Equipment for Residential and Small Commercial Buildings, and CSA-B149.1, Natural Gas and Propane Installation Code. They are intended for installation inside or outside of buildings to provide an essentially vertical conduit or passageway for conveying flue gases to the outer air from the above-described class of appliances.

ULC S629: Standard for factory-built 650C super chimneys. 1200 degrees F continuous, 1600 degrees 1 hour, 2100 degrees F 30min x 3 times. This applys primarly to prefabracated chimney systems.

1 SCOPE-CAN- Partial

1.1 These requirements apply to factory-built chimney assemblies which do not require field fabrication.

They are for use with gas, liquid and solid fuel-fired residential appliances and building heating equipment, where the flue-gas temperatures normally do not exceed 650 ºC. They are intended for use in accordance with the National Building Code of Canada, CSA B139.2, Installation Code for Oil Burning Equipment for Residential and Small Commercial Buildings, CSA B149.1, Natural Gas and Propane Installation Code, and CSA B365, Installation Code for Solid-Fuel Burning Appliances and Equipment. They are intended for installation inside or outside of buildings to provide an essentially vertical conduit or passageway for conveying flue gases to the outer air from the above-described class of appliances.

- What type of chimney do I need based on the climate where it will be installed? Air Cooled or Insulated Chimney pipe?

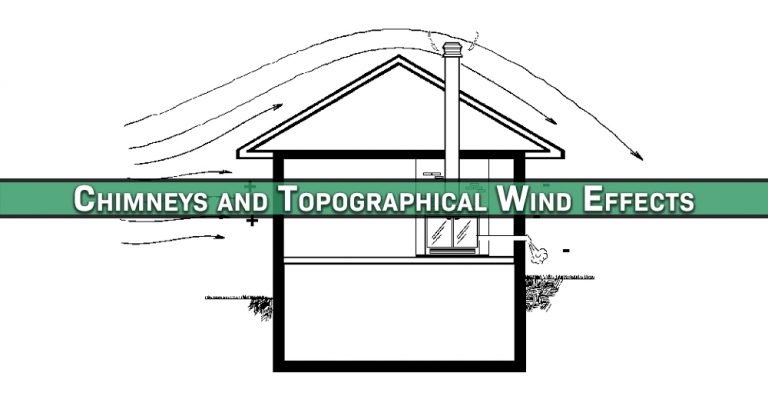

- Where am I installing the chimney, indoors or outdoors? If installed outdoors, will my chimney be exposed to prevailing winds? Do I need chimney designed for frigid climates? Do I need to enclose the chimney inside a chase?

- What kind of building codes do I need to be concerned with?

- UL/ULC Chimney Standards and why they really matter in chimney performance and safety. Should you spend the extra money for the best?

- What UL/ULC listing pertains to my application? Does the chimney I am considering purchasing carry that UL/ULC Certifications?

- Offsets, do I need them? If so how do I support the weight of the chimney above the offset? As well as the chimney below?

- Overhangs, is it wide enough to go through and install a roof flashing? If not, can I fasten a support bracket to the fascia were it will support the chimney for the next 30 yrs?

Tech Tips:

Sometimes a chimney can have too much draft, which you can reduce by installing a biometric damper. This is essentially a chimney with a door that opens to reduce some of the vacuum or draft inside the flue by pulling air into a tee installed near the appliance.

If you are installing an exterior chimney, you can preheat the chimney using a propane torch, or a Draft Inducer which is an electric fan connected to a chimney. A cold chimney will work in reverse until it warms up.

Obadiah’s Woodstoves is one of the oldest online Hearth dealers. The goal here is to share the knowledge of lessons learned so you don’t repeat our mistakes in your installation. Our sales and technical departments are very experienced and knowledgeable. We offer a vast product line, many of which are not on our website yet as the industry is constantly changing. If you are interested in something not found on our website, please call, we can probably help.

If you have a unique project that requires talking with a chimney expert, experienced in industrial, commercial, architectural, restoration, HVAC, we have the ability to do custom design and quotes for many types of venting systems. Just call or email us.

Obadiah’s focus has always been customer service. We have been building Hearth related websites for over 20 years. Some websites are for providing knowledge to the general public so that have a better understanding if they are researching before they purchase. They are our gift to you.

“I know of no time in human history where ignorance was better than knowledge”. – Neil deGrasse Tyson

Please visit our other websites:

https://woodstoves.net

https://www.discountstoves.net

https://www.stove-parts.net

https://www.cookstoves.net

https://wood-boilers.net